Wetmore Roller Mill

Wetmore Roller Mills crimp and crack all grain for livestock and poultry. Fractured grains give extra feeding value and these dustless mills save feed.

WETMORE SINGLE ROLLER

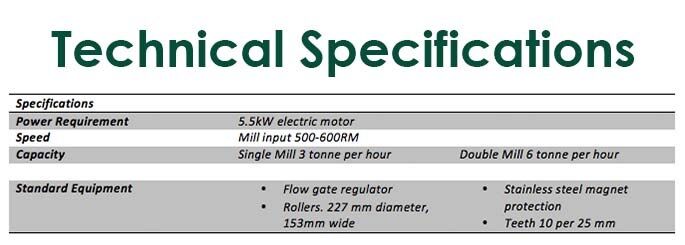

The Single Mill has one hopper feeding the rollers. The double mill has two hoppers combining two roller mills with one power source, driving two pairs of rollers and the discharge auger. This enables the economical milling of different grain combinations which are then mixed in the base hopper and conveyed by the discharge auger. Driven by a 5.5 KW electric motor this tandem mill can process up to 6 tonnes per hour.

The Single Mill has one hopper feeding the rollers. The double mill has two hoppers combining two roller mills with one power source, driving two pairs of rollers and the discharge auger. This enables the economical milling of different grain combinations which are then mixed in the base hopper and conveyed by the discharge auger. Driven by a 5.5 KW electric motor this tandem mill can process up to 6 tonnes per hour.

Able to mill a combination of grains into a balanced, nutritional ration which will enhance production.

Increased palatability and digestibility with fresh feed daily. Independent regulators allow varying granule sizes.

One 5.5 KW power source drives the entire mill and discharge auger. Two pairs of driven rollers doubles the milling rate and are independently adjustable.

Flexibility in discharge auger choice from the standard 45% auger in lengths up to 6m to the alternative 60% base hopper, which will accommodate independent self-powered augers up to 10 metres long.

No additional mixing apparatus is required for mixing all grain varieties.

Easily automated to function unattended when mated with silos and metering augers

WETMORE DOUBLE ROLLER

The Wetmore Twin Roller Mill has two hoppers combining two roller mills with one power source, driving two pairs of rollers and the discharge auger. This enables the economical milling of different grain combinations which are then mixed in the base hopper and conveyed by the discharge auger. Driven by a 5.5 KW electric motor this tandem mill can process up to 45 tonnes of grain per 8 hour day.

The Wetmore Twin Roller Mill has two hoppers combining two roller mills with one power source, driving two pairs of rollers and the discharge auger. This enables the economical milling of different grain combinations which are then mixed in the base hopper and conveyed by the discharge auger. Driven by a 5.5 KW electric motor this tandem mill can process up to 45 tonnes of grain per 8 hour day.

Able to mill a combination of grains into a balanced, nutritional ration which will enhance production.

Increased palatability and digestibility with fresh feed daily. Independent regulators allow varying granule sizes.

One 5.5 KW power source drives the entire mill and discharge auger.

Two pairs of driven rollers doubles the milling rate and are independently adjustable.

Flexibility in discharge auger choice from the standard 45% auger in lengths up to 6m to the alternative 60% base hopper, which will accommodate independent self-powered augers up to 10 metres long.

No additional mixing apparatus is required for mixing all grain varieties.

Easily automated to function unattended when mated with silos and metering augers.

Milling and mixing your own grains with the Wetmore Twin Mill is affordable, profitable and easy.

FEATURE LIST

FEATURE LIST

- New release

- Triple Roller Mill

- (9 ton per hour)

- Design to fit on Vertical mixer and driven with 2 hydraulic motorsSpring release protection to reduce damage and wear.

- Solid Cast rollers are hardened and can be re grooved.

- Robust construction for long with heavy duty bearings.

- Both Powered Rollers prevents whole grain escaping and set stops prevent wear and damage.

- Extensive adjustment by quick action lever copes with a variety of grain.

- Augers up to 6 metres allowing for adaptation to silos and feeding systems.

- Electric, PTO or stationary engine drive

- Flow gate regulator controls milling rate

- Other options available on request

The Double Roller Mill is the same as the single Roller Mill with the following exceptions:-

Dimensions Unpacked – height 1100mm, length without motor 700mm, and width without auger 870mm.

Power Requirement – 5.5 kw electric motor or tractor P.T.O

The standard mill is available as a single ( 3 tonne/hour) or a Double (6 tonne /hour), These units are designed to be floor mounted and can be driven by pto or electric motor, models shown below include optional discharge auger.

As options on our range of vertical feed mixers the mills are usually fitted on the top allowing the treated grain to gravitate into the mix