Vertical Feed Mixer

The Lockwood AG range of feed mixers can chop up and thoroughly mix the complete range of stock feed, whether it be hay, silage, straw, grain and mineral additives plus a host of other products.

The Lockwood AG range of feed mixers can chop up and thoroughly mix the complete range of stock feed, whether it be hay, silage, straw, grain and mineral additives plus a host of other products.

Substantial increases of milk yield in dairy cows or weight gain for all stock are achieved by using fodder mixing trailers.

Due to the mixing of the individual fodder components into a total mixed ration (tmr), the animals can no longer select, thus absorbing the same ration with each bite. Only this ensures optimum physiological feeding of the rumen bacteria.

Adjustable special knives mounted on the auger and adjustable counter-cutters fixed to the container wall facilitate the handling of entire round or large square bales. The characteristic features of the Feed Mixer are its flexibility, its high mixing precision and its low wear with low maintenance costs.

- High mixing precision

- Gentle fodder treatment

- Auger protection against overloading

- Handling of entire large square or round bales

- Simple. low-wear and low-maintenance design

- Robust planetart gear with integrated auger seat

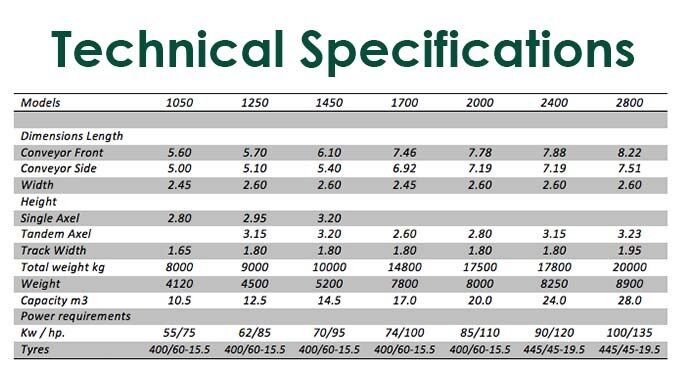

The units range in size from 7.5 M3 to a huge 42 M3. Discharge options are available to feed into low troughs or to high self feeders.

When looking for an extremely strong and long lasting mixer that has excellent resale value

there is no better solution than the Lockwood AG Feed Mixer

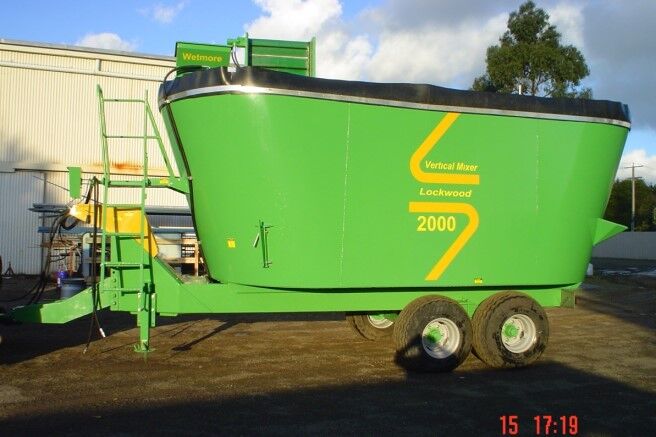

Hydraulically driven Wetmore roller mill

Adding a Wetmore roller mill to your mixer gives you greater flexibility to your operation. These robust units crimp or crack all grains for livestock feed.

Discharge Elevator

Each machine comes standard with a 1200mm side elevator. These elevators can be extended anywhere up to 3.3 metres, enabling the transfer of feed into self-feeders

Counter Cutters

Two manually adjustable counter – cutters facilitate the chopping of round or square bales.

General Characteristics

The particular characteristic features of the Vertical Mixer (single with one auger 750, 1050, 1250 and 1450. Double 1700, 2000, and 2800) are large mixing volume and favourable dimension, both height and width.

Electronic Weigh Scale

The weighing device is an important component of the mixer wagon. The profitability of the fodder mixer can only be made full use of by an exact metering of the individual fodder components.

Driving the Augers of a Double Vertical Mixer

A combined two speed transmission with two output shafts is fitted at the front of the unit. This allows the two auger gearboxes to be driven independently, giving equal protection to both gearboxes.

Mixing Augers

The mixing augers are equipped with sickle-shaped knives which guarantee a fast and exact mixing of all fodder components. Square or round bales are chopped and mixed in by the knives at the same time. An additional clearing device, opposite the auger entry, ensures a consistent unloading.

Discharge Elevator

Each machine comes standard with a 1200mm side elevator. These elevators can be extended anywhere up to 3.3 metres, enabling the transfer of feed into self-feeders

Tandem Axel and Springs

Give a smooth ride and ease of handling on roads or in paddocks with drains in

Mineral Feed Funnel

A mineral feed funnel is standard and fitted at the rear for ease of loading small quantities.

Feature List

Feature List

- Simple construction, minimal wear and low maintenance

- Constructed from 20 mm 350 grade base plate

- 8 mm thick container wall Vert Mix 750 -1450

- Light, quick and exact mixing through a vertical mixing auger, with less power requirement

- Additional scraper on auger for even and faster emptying

- Sabre shaped knives on the auger and opposite direction cutters make the reduction and processing of whole round or square bales effective

- Side elevator available

- Braking axel with parking brake and hydraulic service brake permissible till 6km/hr (optional association)

- 2 speed transmission for the change of the auger speed (with VM 1450 series), optional on smaller models

- Oversized planetary gearbox for all conditions

- Tandem leaf sprung axels on Vert Mix 1250 and 1450 (optional 1050)

- Driveshaft with shear bolt protection

- Tandem Axels with Springs

- Electro Hydraulics

- Side Elevator

- Heavy Duty Chassis

- Scales